TANOI

TANOI has been developing the screw industry by making the most of human resource potential since 1923.

TANOI has started to accumulate and develop a lot of experience in terms of technical, problem-solving and understanding of human communication. TANOI understands that besides technology, the success of production also requires awareness, creativity, openness to new ideas, good relationships and trust from customers. All of these are qualities of people, not machines.

TANOI focuses on the production of threads, so it has a deep understanding of this technology, which is derived from many years of experience in this field. Since customers have many problems in the tapping process, TANOI has passed on the experience to the sales staff through intensive communication. The close cooperation between research, production and sales allows TANOI to share know-how in every part and reach the best skill level of everyone. TANOI’s team not only sells, but also learns the different situations of customers to develop the most suitable working methods for different types of thread production.

Product Information

Double TAFLET – W-TF Series

Up to 4 times more life than conventional thread forming tools by optimizing thread shape and surface coating.

Seamless TAFLET – SL-TF Series

Forming threads by turning clockwise and cutting the tip of the thread when the tap is withdrawn in a counterclockwise manner, making the size of the tip of the thread in the hole consistent, and creating a complete tip of the thread, full tip of the thread.

Zero Chip tap – ZC Series

A new internal tap oil supply system has been designed with a side-through flute to remove as much cutting chips as possible from the workpiece hole, reducing the problem of stuck chips and clogged water holes. This helps increase the efficiency of the coolant, allowing for increased threading speed.

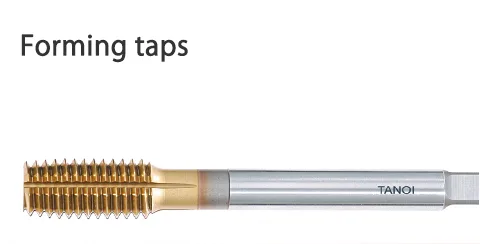

Forming Taps

It is designed for producing internal threads through cold forming process, which is widely used in threading of mild steel, stainless steel and tool steel, as well as non-ferrous metals such as aluminum, etc.

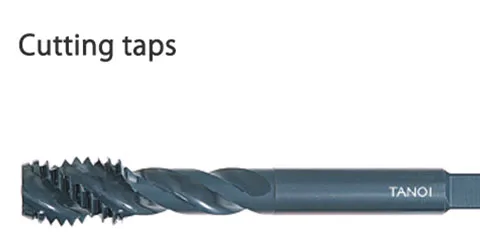

Cutting Taps

Designed for producing internal threads by removing material from the inside of a drilled hole, TANOI offers a wide range of taps including straight flute taps, helix flute taps and serrated end taps, as well as coatings for cylindrical and conical threads.

Cutting Oil

TANOI’s Cutting oils are available in both non-water-soluble, chlorinated and non-chlorinated types, and water-soluble types. TANOI also has Cutting pastes for tapping processes.

Tanoi Products

Reduce tapping time on Aluminum Casting workpieces with Multi-function Taps, new technology from TANOI.

Which type of tap is suitable for your application?

W-TF Double Taflet Tap can tap threads faster and provide a long service life.