GERARDI

The leader in clamping systems from Italy with over 40 years of experience. The highlight is the modular clamping system that allows changing clamping devices to suit clamping different types of workpieces. The quality is guaranteed with a 5-year warranty and usage by customers all over the world.

Work holding system

Gerardi has designed workpiece clamping systems suitable for a wide range of applications, which can be divided into the following main groups:

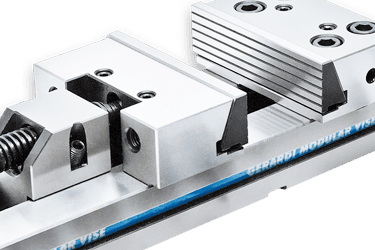

Precision Modular Vises

The most popular standard stylus is a modular stylus with interchangeable parts for different workpiece clamping styles. It is quick to change nibs and is suitable for general work and work that requires multiple workpiece clamping styles.

FMS Vises

A complete range of clamps for machining. Capable of holding all 3 types of workpieces: normal clamping, centering clamping, or centering 2 pieces at a time. Can clamp workpieces automatically with a hydraulic motor and still has Gerardi’s unique features with a modular system with interchangeable accessories for different clamping styles. Suitable for work requiring multiple types of clamping and automatic clamping.

Multiflex Vises

Clamps for clamping multiple shapes and multiple pieces simultaneously. Ideal for small workpieces that require clamping multiple pieces simultaneously to reduce clamping time and still maintain the unique Gerardi properties with a modular system with interchangeable accessories for different clamping styles.

Multitasking Vises

Self-centering vise is designed for use with 5-axis machines, increasing the ability to machine in all 5 directions. It comes with a special grip jaw that can reduce the workpiece holding area but still maintains the same clamping strength. It also maintains Gerardi’s unique modular system with interchangeable accessories for different workpiece clamping styles.

Gerardi designs and manufactures new solutions in the clamping of workpieces and tool holders for milling, drilling and finishing operations.

Gerardi Tooling Equipment

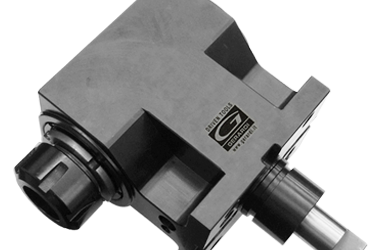

Angle Heads

Evolution Line and Classic Line. Highest accuracy and reliability are the main features

Spindle Speeders

Spindle Speeders Evolution line for milling, drilling and finishing operations

Driven Tools

Driven tools for CNC turning centers allows milling, drilling and tapping operations on the lathes without additional parts handling.